Ervin is always close to the customer. Providing the best standard, we also want to guarantee you find your optimal product for your individual needs. There’s always more than one way to look at an abrasive application, and we’re here to help you find your ideal steel or stainless steel abrasive.

Use our Solutions Finder to narrow your search and explore the products we recommend for you.

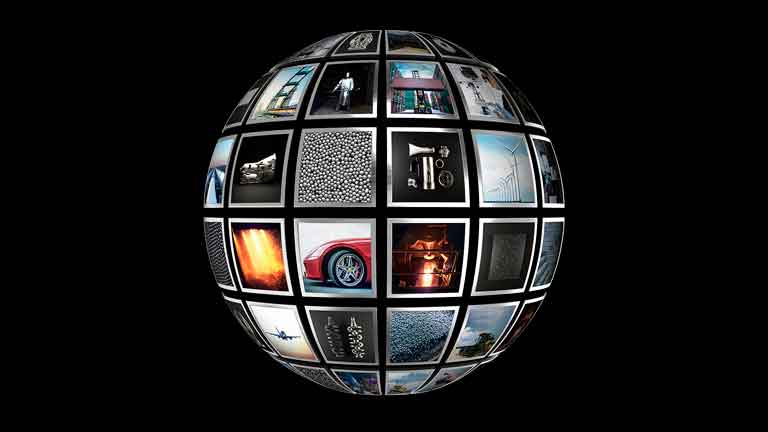

What you can expect when working with Ervin products

As a family owned company we have maintained our belief in doing everything the best possible way since the 1920s, when our founder John F. Ervin first developed the steel abrasive casting process, still used by producers today. We are the original and the best.

Furthermore, our quality measurements have become the standard within the industry – the Ervin Test Machine is the benchmark for all competitors. Every single product in our range is instilled with the innovative, pioneering spirit of John F. Ervin. The World Standard for Quality is the standard we set ourselves, and the promise we make to all our customers and partners.

In tests carried out under laboratory conditions at Ervin, and repeated in our customers’ process, our abrasive consistently outperforms equivalent competitors for durability and transmitted energy. We rigorously pursue optimum levels of hardness, grading, metallurgical microstructure, chemistry and physical form to ensure that our customers can trust our product consistently to perform at the highest levels.

Choosing Ervin steel & stainless steel shot and grit provides an opportunity to reduce total process costs. Our local technical support works closely with customers to optimise the whole blasting process. To find out more about our products click on the images below.

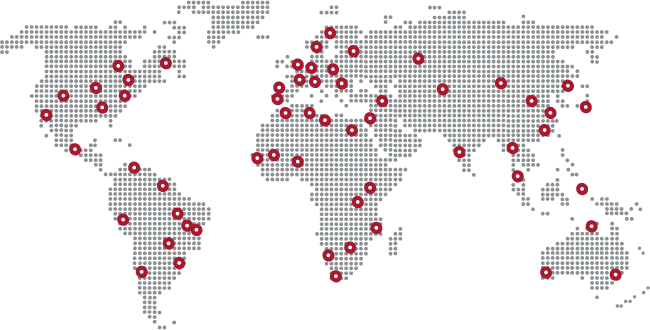

Ervin is close to customers – worldwide! Ervin has several production facilities in USA and Europe. Through the worldwide net of sales offices and distributors Ervin offers products and services close to customers.

Contact

Select the application type you’d like solutions for

{{ steps_labels.step_2.text }}

{{ steps_labels.step_3.text }}

{{ steps_labels.step_4.text }}

Contact our experienced sales team to discuss your requirements.

Contact